Industrial CT Scan of Aviation Connectors: A Deep Dive into Non-Destructive Testing

- Apr 15, 2024

- 2 min read

Updated: Feb 12, 2025

Introduction

In the world of aerospace and aviation, precision is paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One such component is the aviation connector. These high-performance, harsh environment connectors are vital for ensuring the seamless operation of various aircraft systems.

The Power of CT Scanning

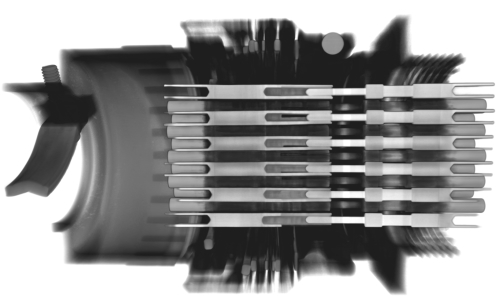

Industrial Computed Tomography (CT) scanning has emerged as a powerful tool for inspecting these connectors. Unlike traditional methods, CT scanning is a non-destructive technique, meaning it allows for the inspection of a component’s internal structure without causing any damage.

CT scanning compiles digital x-rays into a 3-dimensional volume of the actual part, resolving internal structures that can be sliced and measured digitally. This technology provides a closer look at the interior makeup of assemblies and engineering components than a standard 2D x-ray can provide.

Applications in Aerospace

CT scanning is particularly beneficial in the aerospace industry. It can be used across a wide variety of materials and methods, such as investment castings, additive manufacturing, and carbon fiber composites. It ensures the component is intact upon testing completion and detects flaws or defects that may not be detected during destructive testing.

For instance, CT scanning can be used to inspect pin positions and mating on multi-pin connectors, check for wire nicking and fraying, examine crimp joint integrity, inspect wire insertion position, detect foreign object debris (FOD), and check insulation integrity and position.

Conclusion

In conclusion, the use of CT scanning in the inspection of aviation connectors is revolutionizing the aerospace industry. By providing a non-destructive method of inspection, it ensures the safety and longevity of these crucial components. As the technology continues to advance, we can expect to see even more applications and benefits from this innovative technique.

Comments