Battery Inspection with Micro-CT

Battery CT scanning / Micro-CT inspection for R&D, quality, product development and failure investigations

Computed Tomography (CT scanning), often referred to as Micro-CT or 3D X-ray are key to understanding the jelly roll of traditional batteries and the internal details of new designs. This technology allows designers, engineers and investigators to inspect internal features of the cathode and anodes without disassembly.

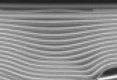

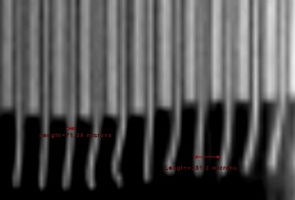

Damaged 18650 Battery

Micro-CT inspection of this 18650 battery cell provides X, Y & Z views of the internal details of the jelly roll, allowing our customers to more easily identify defective units.

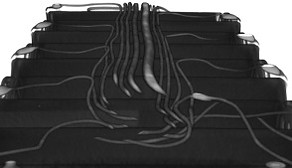

Ebike Battery

Using industrial computed tomography, we can detect defects and internal changes in lithium-ion batteries and allow our customers in inside view into the mechanical workings of their product without sectioning or destroying the assembly.

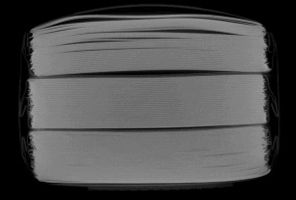

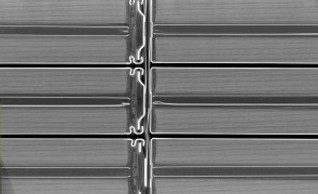

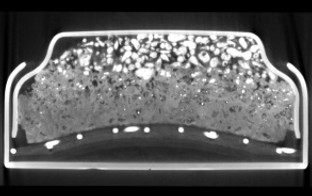

Hi Discharge Li-Po Battery

Once a battery has been CT scanned and a digital 3D model has been created, the images can be viewed on a computer monitor, digitally rotated for various viewing angles, sliced to form section planes and filtered to remove obstructive content.

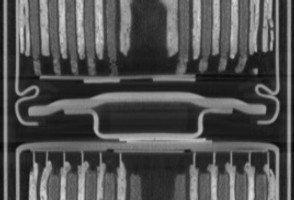

Lithium Ion Battery

CT scanning batteries can help identify irregularities between the anode and the cathode within the "jelly roll. In addition, it allows forensic investigators to inspect burnt remains after a fire, helping find the root cause of the fire.

18650 Lithium Ion Battery

Our standard CT scan deliverables include dimensioning tools that allow you to drop measurements in 2D slices as you need. Our 3D CT services are a great choice for first article inspection (FAI) as our customers do not need to cut open or section their parts.

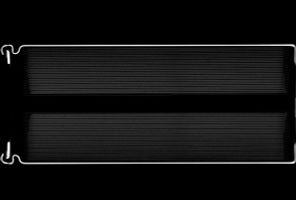

Laptop Battery Pack

Our system is capable of CT scanning an entire battery pack such as this laptop battery pack with 12 battery cells.

Rechargeable Battery

Button Battery

Our executable software that we deliver with all CT scans allows you to slice in any plane at any depth on the part imaged.

Flat Battery

Using our 3D Xray services, customers can inspect the jelly roll of rechargeable batteries such as this action camera battery.